Machine Learning for Predictive Maintenance: Reinventing Asset Upkeep

Across industries, corporations have historically relied on scheduled upkeep. Looking into the innards of machines at set intervals does maintain them working. But is it actually essentially the most cost-effective manner of slicing undesired downtime? Not actually. Numerous research say that solely 20% of kit failures are age-related, whereas 80% happen randomly.

With companies throughout sectors warming up towards all issues AI, machine studying predictive upkeep has gotten into the highlight.

Foreseeing gear points earlier than they happen and performing upkeep precisely when it is wanted guarantees value financial savings and improved productiveness. In reality, 90% of producers who adopted machine learning-based predictive upkeep managed to chop restore time and unplanned downtime, says a analysis carried out by CXP Group.

In this weblog put up, we share our expertise in AI software program consulting, dig into the innards of predictive upkeep programs, share success tales to get impressed by, and contact upon the challenges of adopting AI predictive upkeep options.

First issues first: what’s predictive upkeep?

Predictive upkeep is a proactive strategy to gear maintenance that makes use of machine studying to foresee potential failures. This, in flip, helps stop pricey downtime.

Think of it as having your gear speaking, telling you precisely when it wants consideration, simply earlier than one thing goes improper.

A predictive upkeep system works like a crew of inspectors watching over your gear 24/7, amassing and crunching huge volumes of knowledge in actual time. These “inspectors” can detect the smallest anomalies and patterns that escape the human eye, warning you of potential failures earlier than they turn out to be main complications.

Now, let’s take a look at an instance to see how the idea works in observe. Imagine a producing plant that depends on a fleet of commercial robots to maintain operations working. Traditionally, upkeep for these robots was scheduled at mounted intervals or, worse, when a breakdown really occurred, inflicting downtime and monetary losses.

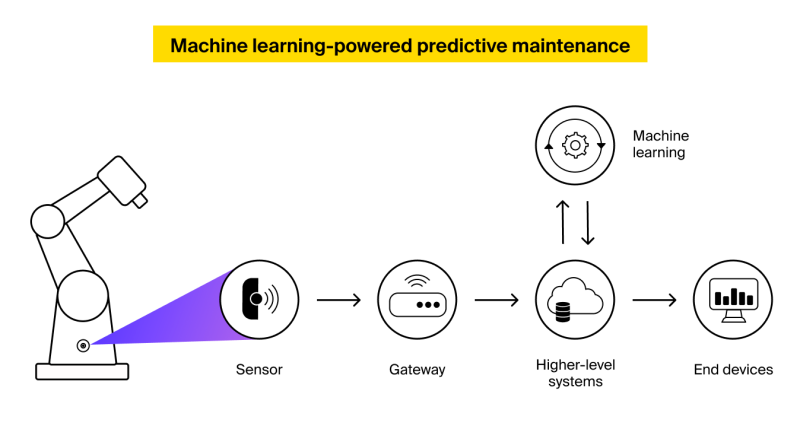

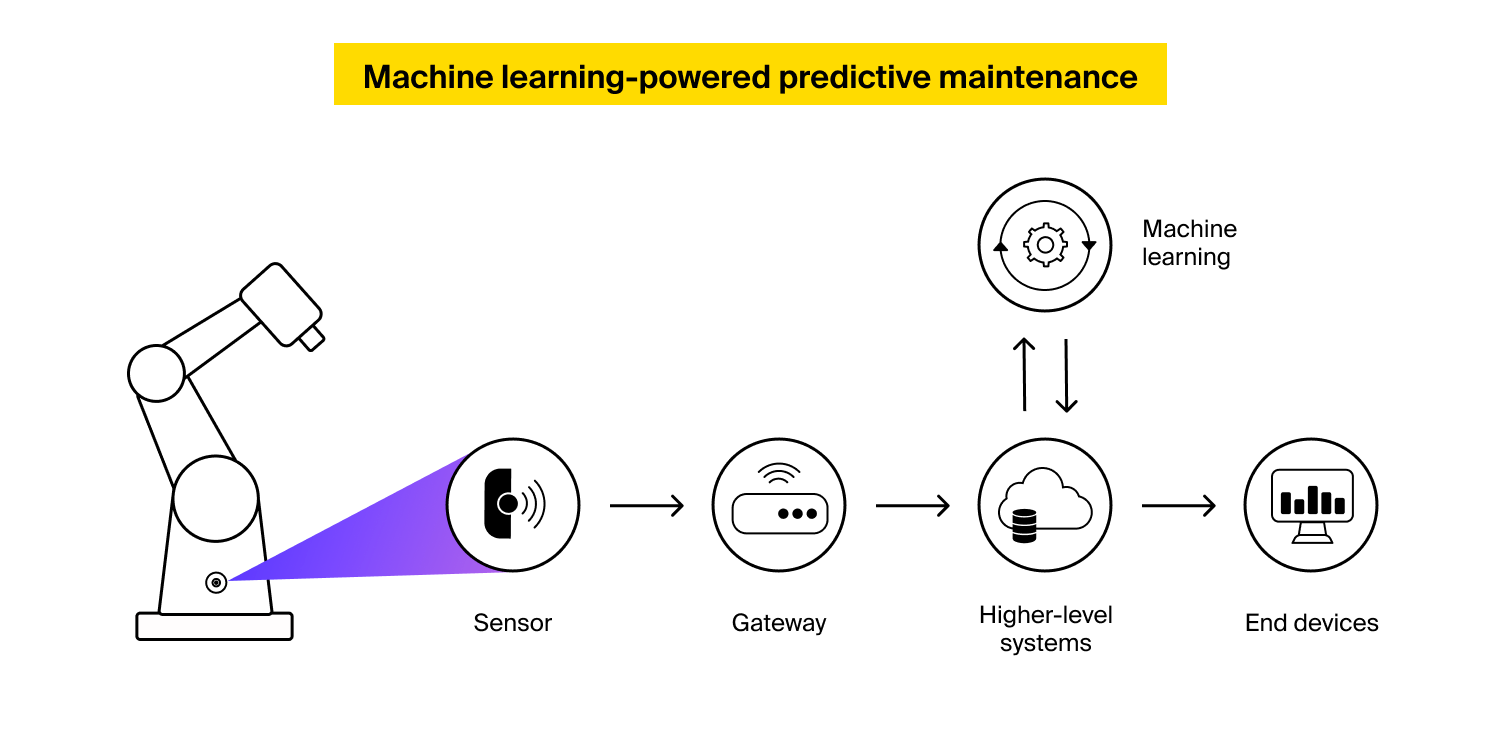

With machine studying predictive upkeep, gear is being continuously monitored with the assistance of sensors strategically embedded into the machines. The knowledge gathered can span temperature, vibration, energy consumption, and different metrics.

All this knowledge is then despatched to the mind of the system powered by machine studying algorithms. Drawing on historic breakage knowledge, restore historical past, environmental components, and efficiency metrics collected in actual time, the mind seeks out patterns which may sign an upcoming malfunction.

Armed with these beneficial insights, your upkeep crew can swoop in, perform the wanted fixes, and forestall the looming breakdown from ever taking place. All that with minimal downtime and no pricey disruptions.

And that is precisely the place the cost-saving potential of machine studying predictive upkeep comes from. Due to its proactive nature, you may focus your efforts and budgets on the gear that actually wants consideration – as a substitute of losing assets on catering for the gear that’s completely advantageous. On the opposite hand, with the facility of foresight, you may act earlier than an issue escalates, making certain that your gear operates at peak efficiency for longer intervals.

Use instances of AI predictive upkeep throughout sectors

AI-driven predictive upkeep is essentially reworking the best way equipment-dependent industries run. Below, we present examples showcasing the influence predictive upkeep can drive.

Manufacturing

In discrete and course of manufacturing, AI predictive upkeep proves invaluable for a wide selection of kit, together with milling machines, hydraulic presses, conveyor programs, robotic arms, and others.Consider milling machines that form uncooked supplies into precision elements. Equipping these machines with vibration sensors and analyzing sensor readings in opposition to historic failure knowledge will help detect misalignment and indicators of damage in machines’ spindles. And monitoring temperature, chances are you’ll catch indicators of overheating signaling {that a} malfunction could be brewing.

The energy of machine learning-based predictive upkeep would not cease there. Hydraulic presses will be monitored for clogs and leaks that ship a sign about malfunctioning. Additionally, by way of fixed temperature monitoring, predictive upkeep options could detect indicators of overheating, a purple flag for impending points throughout the hydraulic system. And with the power to rely cycles, machine studying predictive upkeep could precisely predict when particular elements could require consideration, enabling well timed upkeep interventions and stopping potential breakdowns.

When it involves conveyor belts, predictive upkeep software program can measure belt stress to stop untimely put on. And by monitoring motor load, it might guarantee effectivity and uncover any hints of bother that might trigger sudden downtime.

Among producers utilizing predictive upkeep is Mercer Celgar, one of many largest pulp and stable wooden producers. Predictive upkeep has turn out to be a key a part of the corporate’s manufacturing technique.After exploring numerous choices, Mercer Celgar carried out an off-the-shelf predictive upkeep resolution. This AI-powered software program seamlessly built-in with their new CMMS system, changing the earlier automated machine well being diagnostic software program. Through three pilots, the deployment yielded beneficial insights and learnings.

With the AI-based predictive upkeep platform in place, Mercer Celgar gained the power to watch a number of manufacturing traces and acquire particular person stories for every machine sort inside a single platform. This allowed them to trace and examine efficiency whereas offering early insights to their upkeep groups concerning potential breakdowns and failures.The implementation remodeled Mercer Celgar’s operations, creating particular job roles and centralizing machine efficiency knowledge from a number of sources into one platform. As a outcome, they’ve a single supply of reality for machine efficiency, facilitating environment friendly monitoring and knowledge processing at scale.

Automotive

The automotive business closely depends on machine learning-based predictive upkeep to boost reliability and cut back guarantee prices. By monitoring sensor knowledge from automobiles within the subject, for instance, automakers can detect potential points earlier than they turn out to be important failures.

Let’s take into account a fleet of supply vehicles. Through steady monitoring of engine efficiency, tire situation, and gas effectivity, predictive upkeep allows corporations to optimize upkeep schedules, stop breakdowns, and lengthen the lifespan of their automobiles.

Quite a lot of automotive corporations have turned to predictive upkeep to anticipate upkeep alternatives and retain prospects, encouraging them to hunt upkeep companies from the automotive producer’s official community. One such firm is Opel, which has geared up its automobiles with a predictive upkeep instrument that analyzes historic knowledge to recommend optimum inspection schedules.

As the principle goal of implementing the system is to enhance buyer retention, the system notifies drivers when upkeep is due and arranges appointments with Opel’s official community, discouraging prospects from turning to third-party repairers.

Healthcare

Machine studying predictive upkeep is revolutionizing the healthcare business, making certain the sleek operation of important medical gear. Picture an MRI machine in a hospital. By analyzing sensor knowledge, together with temperature, strain, and electromagnetic subject energy, predictive upkeep algorithms can detect anomalies, deviations, and patterns indicative of potential points. Hospitals can then proactively schedule upkeep actions throughout low-demand intervals, minimizing disruptions to affected person care. This strategy results in improved operational effectivity, lowered gear downtime, and enhanced affected person outcomes.

One healthcare group to embrace such an strategy is Kashiwa Health Check Clinic. They’ve partnered with Hitachi to implement a predictive upkeep system to stop MRI machine failures. The expertise accomplice analyzed three years’ value of sensor knowledge from 100 MRI programs and created a mechanism to analyze the trigger patterns that result in machine failures. Machine studying then helped to outline a standard operational state, foresee abnormalities, and detect modifications that result in failures. As a outcome, the group lowered MRI machine downtime by 16.3%.

Oil & gasoline

The oil and gasoline sector, recognized for its intricate and costly gear, advantages immensely from machine learning-based predictive upkeep. Imagine an offshore drilling rig with quite a few pumps, compressors, and generators. Through steady monitoring of parameters like strain, temperature, and movement fee, predictive upkeep algorithms can detect anomalies and predict impending failures. By taking a proactive strategy, corporations can keep away from pricey unplanned shutdowns, optimize gear efficiency, and make sure the security of personnel.

Aramco, a number one participant within the manufacturing business, has harnessed the facility of predictive upkeep to stop corrosion, scaling, and different harm of kit and pipelines attributable to extra water coming from wells along with oil and gasoline. Having carried out an AI-powered movement meter, the corporate gained a real-time perception into water movement within the wells. This meter employs an AI-powered digital twin mannequin to anticipate pipe movement after which compares it with the precise measurements. This course of allows the meter to mechanically regulate itself throughout numerous working situations, tremendously minimizing recalibration necessities.

How to construct a predictive upkeep resolution?

When it involves adopting machine learning-based predictive upkeep options, organizations face a call: choose for off-the-shelf software program or put money into a custom-built resolution. Each strategy presents distinct benefits and concerns, and the selection will depend on a number of standards:

- Available funds: Off-the-shelf software program (e.g., IBM Maximo, Microsoft Azure IoT Suite, GE Predix, PTC ThingWorx, Siemens MindSphere, and others) typically comes with decrease upfront prices, whereas constructing a {custom} resolution can contain the next preliminary funding. Companies with restricted budgets could discover off-the-shelf software program extra interesting, whereas these with substantial assets may lean in the direction of {custom} options for tailor-made performance.

- Time-to-implementation: Off-the-shelf software program will be rapidly deployed since it’s pre-built and examined. In distinction, creating a {custom} resolution could take longer, relying on the complexity and scope of the mission.

- Industry-specific necessities: Different industries usually have distinctive wants and workflows that require predictive upkeep options to have particular options. Off-the-shelf software program doesn’t absolutely align with these necessities and wishes customization. So, companies with extremely specialised wants or these in search of a aggressive edge by way of tailored options could desire to go the {custom} route.

- Existing infrastructure and integrations: Integrating predictive upkeep software program with present programs and gear is important for seamless operations. Off-the-shelf options could provide higher compatibility with a restricted variety of common items of kit or applied sciences, whereas {custom} options will be exactly tailor-made to suit into a company’s established infrastructure.

- Scalability: As companies develop and develop, their predictive upkeep wants could evolve. Off-the-shelf software program could present scalable choices that may be tailored to altering necessities. When correctly designed, {custom} options may also provide scalability and adaptability, however this may require further improvement effort.

- Support and updates: Off-the-shelf software program usually comes with vendor-provided help and common updates, making certain the answer stays up-to-date. Custom options could require ongoing upkeep and help efforts to make sure continued performance.

Building an AI-based predictive upkeep resolution from scratch

Building a {custom} machine learning-based predictive upkeep resolution from scratch offers most flexibility and permits you to tailor the system exactly to your distinctive wants. Still, {custom} software program isn’t absolutely {custom}. There are quite a lot of open-source libraries and frameworks (e.g. Scikit-learn, TensorFlow, PyTorch, Keras, XGBoost, and many others.), SDKs and APIs (e.g., AWS SDKs, Azure SDKs , Google Cloud SDK, IBM Watson SDK, ThingWorx SDK, and many others.), in addition to absolutely managed machine studying companies together with pre-trained fashions (e.g., Amazon SageMaker, Azure Stream Analytics) that pace up and simplify the method of creating {custom} predictive upkeep options.

Below, we share our expertise working as an ML consulting firm and clarify how the method of creating AI-based predictive upkeep software program could unfold.

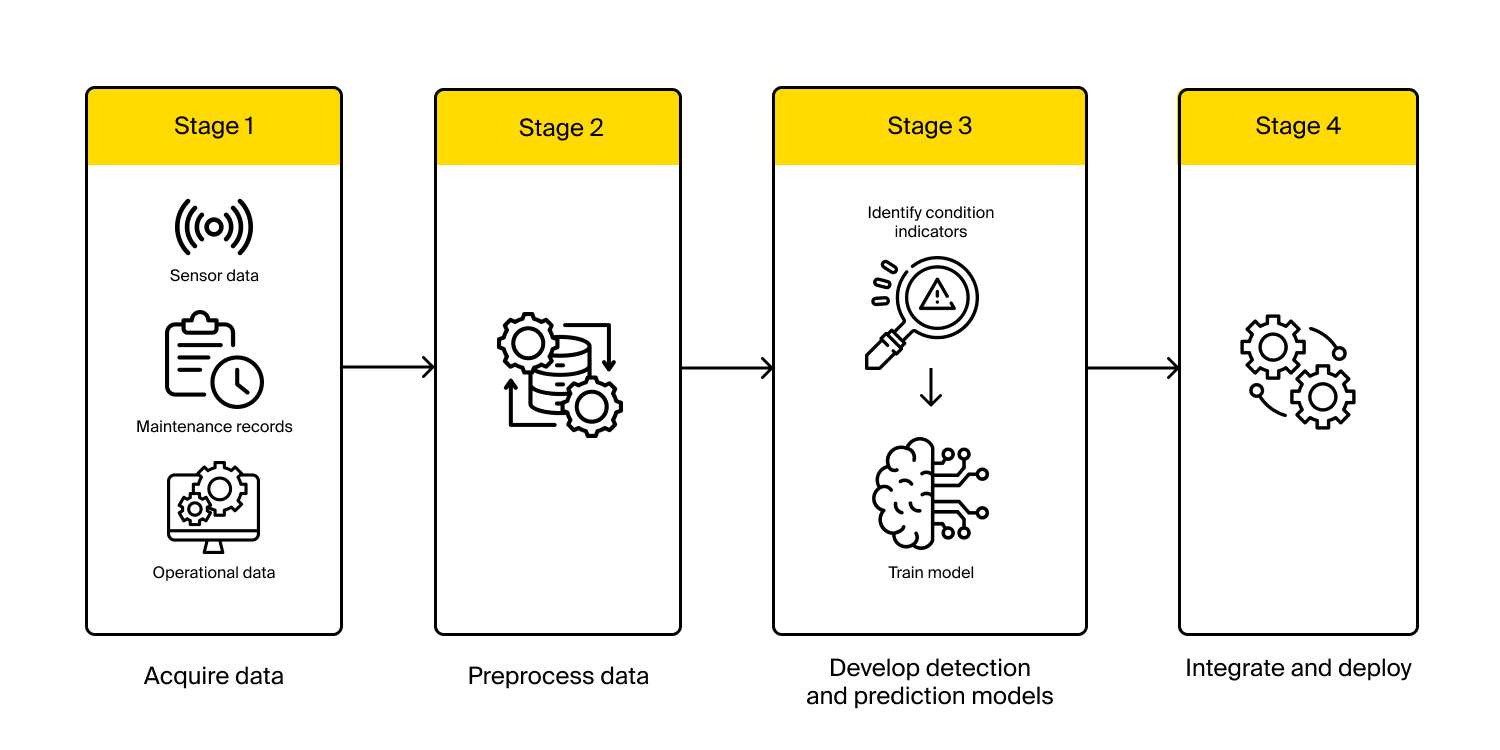

Predictive upkeep is a activity that may be divided into two sub-tasks: situation monitoring and predictive analytics. So, crafting a predictive upkeep resolution primarily boils right down to coaching a detection mannequin and a prediction mannequin and integrating them right into a full-fledged resolution. To practice such fashions, you undergo the next steps:

Data assortment

When crafting a predictive upkeep algorithm, step one is to collect adequate knowledge for coaching the fashions. The sorts of knowledge to gather span:

- Sensor knowledge that provides real-time perception into the well being and efficiency of machines. It contains time-series data collected from all sorts of sensors (e.g., temperature, strain, vibration, voltage, noise, and extra) connected to machines.

- Failure knowledge that spans details about previous gear failures, together with the date, time, and nature of the failure.

- Maintenance information, service stories, work orders, and different documentation associated to the gear’s upkeep historical past.

- Operational knowledge that captures details about a machine’s operational standing, together with begin and cease occasions, manufacturing charges, throughput, and utilization patterns.

- Environmental knowledge that spans components corresponding to ambient temperature, humidity ranges, and different exterior situations that will influence gear’s well being.

- Other related knowledge that will present further perception into failure patterns, say, vitality consumption or upkeep value knowledge.

Data processing

Data preprocessing is a vital step in constructing a {custom} AI-driven predictive upkeep resolution. It entails a variety of strategies, from dealing with lacking values to eradicating outliers and past.

The selection of the suitable processing strategies will depend on the traits of your knowledge, whereas the important thing to efficiently carrying it out is understanding your machines. Suppose you could have noisy vibration knowledge. Knowing the frequency vary that incorporates markers of failure can information you in selecting the optimum preprocessing technique.

Feature engineering

Feature engineering means reworking uncooked knowledge into options that assist distinguish between regular and defective habits. The objective is to extract related data from the info, making it simpler for machine studying algorithms to determine patterns and relationships.

For instance, you may monitor the situation of a gearbox utilizing vibration knowledge. Malfunctions of a gearbox lead to modifications in vibration frequency and magnitude. Peak frequency and magnitude can, thus, be used for monitoring gearbox well being.

Some frequent strategies utilized in function engineering span:

- Aggregation: Combining a number of uncooked knowledge factors to create aggregated options can present a higher-level view of the gear’s habits.

- Time-based evaluation: Time collection knowledge usually incorporates beneficial temporal patterns. Creating time-based options like time of day, day of the week, or seasonal patterns will help the mannequin seize recurring behaviors.

- Signal evaluation: Applying sign processing strategies will help extract frequency elements or detect patterns in time collection knowledge.

- Correlation evaluation: Assessing which knowledge impacts the accuracy of prediction essentially the most and eliminating these knowledge factors which have much less significance in relation to mannequin coaching from the info set helps lower the time it takes to coach them.

- Domain-specific function extraction strategies: In some instances, area data can result in specialised function transformations. For instance, for rotating gear, options primarily based on vibration order evaluation will be helpful.

Feature engineering is prone to be a course of that will contain a number of iterations. It is frequent to get again to this step after an preliminary spherical of coaching and testing a predictive mannequin for optimum efficiency.

Model choice and coaching

As the subsequent step, you select an optimum machine studying mannequin and practice it on the collected knowledge.

Model choice

Choosing the fitting machine studying algorithm or predictive mannequin is crucial for your particular predictive upkeep use case. Different fashions have various strengths and weaknesses, and the choice will depend on components like the character of the info, the complexity of the issue, and the specified degree of interpretability.

The fashions generally used for predictive upkeep embody:

- Logistic regression: Suitable for binary classification issues, for occasion, predicting whether or not a chunk of kit will fail or not.

- Decision bushes: Effective for dealing with each categorical and numerical knowledge; can seize nonlinear relationships between options.

- Random forest: An ensemble methodology that mixes a number of choice bushes for improved accuracy and robustness.

- Support Vector Machines (SVM): Useful for classification duties, particularly when coping with high-dimensional knowledge.

Model coaching

Model coaching entails utilizing historic knowledge to show the machine studying predictive upkeep mannequin to acknowledge patterns and relationships between options and the goal variable, like gear failure. The dataset is split into two elements: the coaching set and the testing set.

The mannequin learns from coaching knowledge and turns into able to making predictions primarily based on the patterns it identifies throughout the coaching course of.

Once skilled, the mannequin is put to the take a look at on the testing knowledge set. Model validation is a important step to judge how properly the mannequin performs on unseen knowledge and to estimate its predictive energy.

Integration and deployment

Once you have recognized the fitting mannequin, skilled it, and generated correct predictions, it is time to put it into motion by integrating it into your system. Depending on the specifics of your machine studying predictive upkeep software program, you could have a number of deployment choices:

- Cloud implementation: Opt for a cloud-based deployment if you happen to’re coping with giant volumes of knowledge saved within the cloud. By working the machine studying algorithms immediately within the cloud, you get rid of the necessity to switch knowledge forwards and backwards between native machines and the cloud for prognostics and well being monitoring. This streamlines the upkeep course of and enhances effectivity.

- Edge implementation: Alternatively, you may run the algorithm on embedded units positioned nearer to the gear. This strategy permits fast updates and notifications about gear well being with none delays.

- Hybrid implementation: You may also go for a mix of cloud and edge. Utilize embedded units for preprocessing and have extraction and run the predictive mannequin within the cloud. This manner, you get the perfect of each worlds – the effectivity related to edge deployment and cloud-based processing energy. It works notably properly for programs like oil drills or plane engines, the place steady operation generates huge quantities of knowledge, making onboard storage or transmission difficult because of bandwidth and price limitations.

Challenges to handle on the best way

Implementing an AI predictive upkeep resolution could include sure challenges. Some frequent obstacles embody:

- Legacy gear: Connecting and amassing knowledge from older or incompatible gear is usually a problem. Retrofitting sensors or using IoT gateways could also be mandatory to collect the required knowledge.

- Establishing right parameters: Identifying essentially the most related parameters to watch for every bit of kit is essential. This requires a deep understanding of the equipment and its failure modes to make sure correct predictions.

- Data high quality and availability: Ensuring knowledge high quality and availability is important for correct predictions. Incomplete or unreliable knowledge can result in incorrect upkeep selections. Establishing knowledge governance practices and investing in knowledge infrastructure are important steps to beat this problem.

To sum it up

AI-driven predictive upkeep presents a game-changing alternative for corporations working in equipment-heavy or equipment-dependent industries. By embracing the proactive strategy to upkeep, organizations can considerably cut back downtime, optimize upkeep prices, and improve operational effectivity.

Whether by customizing off-the-shelf software program or constructing a {custom} resolution from scratch, machine studying predictive upkeep will help you to unleash the complete potential of your gear.

Contact our crew to discover the chances of machine studying predictive upkeep and make knowledgeable selections that can drive your organization to new heights.

The put up Machine Learning for Predictive Maintenance: Reinventing Asset Upkeep appeared first on Datafloq.